2025 / 05 / 13

How to Find Cost-Effective Nitrous Oxide Tank Prices?

Table of Contents

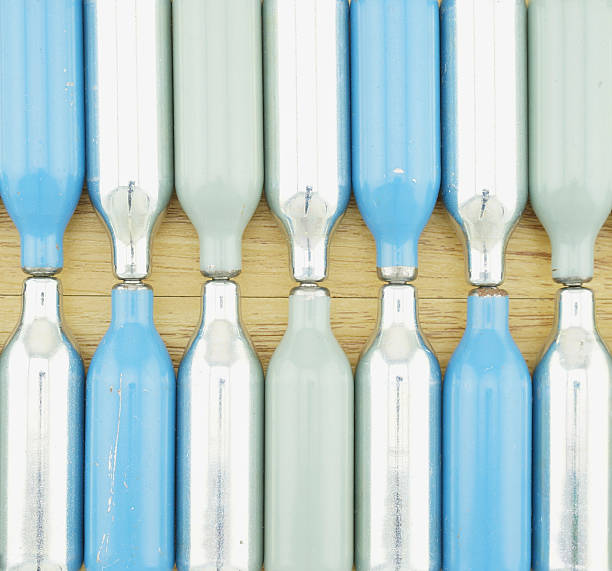

Nitrous oxide tanks have many uses in healthcare anesthesia, food processing, industrial manufacturing and even aerospace propulsion. When searching for cost-effective products while meeting safety and compliance criteria, buyers need to consider several factors including price composition, procurement channels and lifecycle costs. This article offers systematic solutions tailored specifically for users with specific needs while taking into account current industry trends for 2025.

What Affects Nitrous Oxide Tank Prices?

Price Stratification by Capacity and Application

Nitrous oxide tanks prices depend primarily on their capacity and application; their market positioning determines which specifications correspond with which market positions.

- Small food-grade tanks (8g – 640g): used for making homemade cream at home and commercial desserts. 8g disposable aluminum tanks typically cost 0.5-1.5 US dollars and should be suitable for occasional home use; while rechargeable tanks with pressure valve designs that support over 80 uses each can help catering enterprises cut costs by 20% per consumer consumable.

- Large industrial storage tanks (470L+): Widely used for chemical reactions and rocket propellant storage, prices typically range from 2,000 to tens of thousands of US dollars. Customized pressure ratings between 300-500bar may also be necessary, along with safety certifications – cryogenic storage tanks used by NASA must pass their material compatibility tests, with certification fees accounting for 15% of total costs.

- Medical-specific tanks (10L – 50L): Used with anesthesia machines, prices typically range from 500-1,500 US dollars. They must acquire ISO 13485 medical device certification as well as aseptic surface treatment which increases base price by 25%.

Material and Certification Impact on Pricing

Material selection can have significant cost impacts; aluminum tanks have become the preferred food-grade material due to their comprehensive benefits in food-grade markets.

Lightweight aluminum tanks: Although lightweight aluminum tanks cost 20-30% more than carbon steel tanks, their corrosion resistance is 50% higher and 95% of material is recyclable, with recycling value covering 15% of initial cost. A 640g aluminum food tank costs $85.99; carbon steel may have lower initial costs but its failure rate due to rust within two years can reach as high as 30%.

Certification additional costs: Compliance requirements in particular markets can drive up costs significantly – FDA food contact certification increases prices by $10-50 per can while EU CE-PED industrial pressure certification adds 10-20% more. China implemented the GB 7718 standard in 2025 which requires migration limits marking; this requirement has dramatically increased price transparency by 40% as well as caused noncompliant small manufacturers to slowly withdraw from the market.

Procurement models allow more price flexibility

Prices among various channels can differ significantly, necessitating strategic choices.

- Retail Channels: Amazon and GreatWhip offer single-can purchasing platforms, where a 615g food can costs approximately $99.99 with between 15-20% markup from both platforms and logistics fees included in its cost. It provides fast delivery as well as flexible returns/exchange policies making these ideal solutions for small-batch orders with quick delivery times and returns/exchange policies.

- Wholesale channels: B2B platforms such as Alibaba provide bulk discounts (minimum order of 100 pieces), with unit prices for 640g food tanks reaching $5.7-$6.3 per unit, representing a 30% reduction. It is wise to be wary of minimum order quantity risks; one bakery misjudged demand and overstocked 2,000 industrial tanks which were later sold for 50% discount!

One Way To Locate Nitrous Oxide Tank Prices

Compare Cost-Efficient Procurement Channels

Select channels based on purchase volume and industry needs in order to achieve the optimal balance:

B2B Factory Direct

Alibaba’s suppliers provide factory direct supply (Industrial/Bulk purchase), offering 470L industrial tanks for $2.5 – $3.5 per kilogram with minimum orders of 8,800 kilograms; additionally they support third-party factory audits and savings of 35% over local distributors for one chemical enterprise.

B2C Vertical E-commerce (Food/Household)

The GreatWhip 640g food tank set with regulator is offered at $85.99 with an user rating of 4.8/5, offering efficient long-term use due to its patented valve design which reduces gas leakage by 12% for greater economy.

Avoiding the Low Price Trap

To maintain rational prices by carefully scrutinizing suppliers: Demand certifications in specific regions such as CE/PED, FDA or GB/T 23793. Uncertified products could use recycled materials or bypass testing requirements altogether.

2025 Trends: Predicting Nitrous Oxide Tank Price Movements

Sustainable Materials’ Price Impact

Environmental policies make these options more cost-effective:

Aluminum tanks have the advantage of lower full life cycle costs than carbon steel ones: While their initial price may be 15% higher, once disposal rebates and subsidies (like China’s “dual carbon” policy) have been factored into account, their full life cycle costs are 22% lower.

Price optimization through technological innovation

New materials and intelligent designs are revolutionizing market competitiveness: Lightweight designs reduce logistic costs: For example, aluminum tanks featuring 30% weight reduction have dramatically cut ocean freight from $15 per 640g tank down to $12; this represents a savings of 5 USD in unit price for international buyers.

Q&A About Nitrous Oxide Tank Prices-Related

Question: Why do food-grade and industrial tanks differ by 40%?

Answer: The price difference stems from differences in materials and certifications. A food-grade aluminum can must pass an FDA migration test (each test costs $30), then coated with food-grade coating at an additional cost of $15; in comparison, industrial-grade carbon steel tanks do not require such treatments, creating an approximate $25 difference in pricing.

Question: What risks are associated with low-priced, uncertified tanks?

Answer: It is possible to use recycled aluminium (with heavy metal risks) or untreated carbon steel (which has low compressive strength). In either case, pressure tests cost $20 every time and there exists the possibility of leakage or explosion.

Final Thoughts

By thoroughly examining price drivers, selecting optimal procurement channels, and calculating full life cycle costs, purchasers can find cost-effective solutions within compliance parameters. As regulations tighten and innovation advances quickly, adopting sustainable procurement strategies not only controls costs but can reduce long-term risks as well. Put the above strategies and tools to good use immediately so you can start purchasing nitrous oxide tanks effectively.