2025 / 04 / 28

Why is Industrial Nitrous Oxide Vital for Semiconductor Production?

Table of Contents

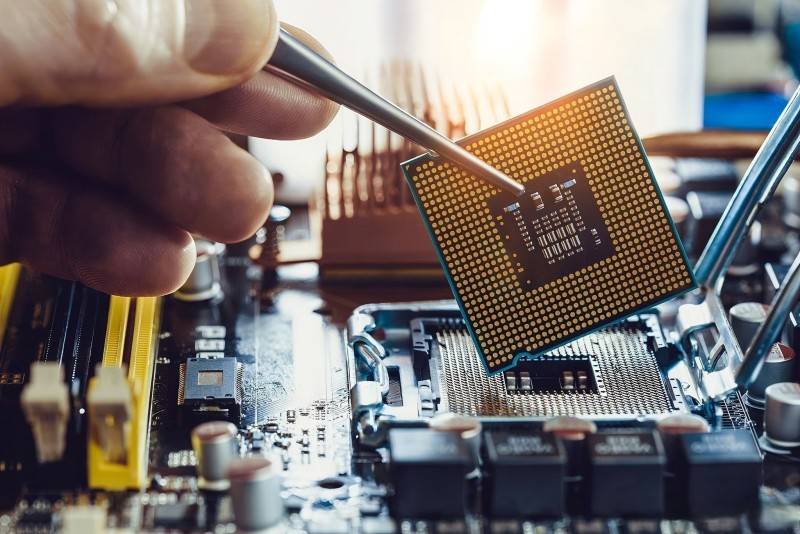

As the world becomes more digitally driven, the demand for faster, smaller, and more efficient semiconductors has never been higher. At the heart of this booming industry lies a surprising chemical hero: industrial nitrous oxide. Known more commonly as laughing gas in the medical field, nitrous oxide (N₂O) is a powerful oxidizer with unique chemical properties that make it indispensable in chip fabrication processes. In this article, we explore the industrial uses of nitrous oxide, its critical function in semiconductor manufacturing, and the essential role of industrial nitrous oxide tanks in ensuring safe and efficient delivery.

What Is Nitrous Oxide and Its General Industrial Uses?

Nitrous oxide (N₂O) is a colorless, non-flammable gas with a slightly sweet odor. While it’s widely known for its anesthetic properties in medical and dental applications, its industrial relevance goes far beyond that.

Key Nitrous Oxide Industrial Uses:

- Semiconductor manufacturing: Used in oxidation and chemical vapor deposition processes.

- Automotive: Enhances engine performance as an oxidizer in racing engines.

- Food processing: Acts as a propellant in whipped cream dispensers.

- Medical: Functions as an anesthetic and analgesic.

- Chemical industry: Serves as a precursor for various syntheses.

The focus of this article is its rising importance in the electronics sector, especially semiconductor fabrication, where it plays a vital role in the manufacturing of integrated circuits.

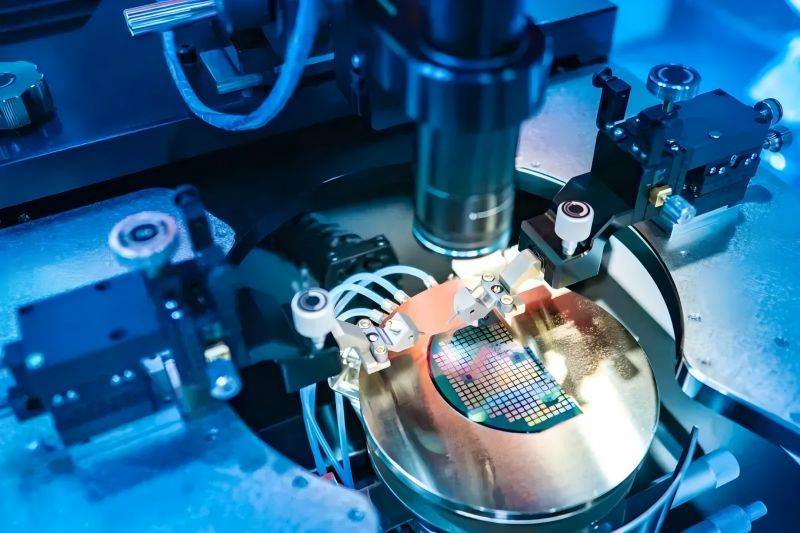

The Role of Nitrous Oxide in Semiconductor Manufacturing

The semiconductor manufacturing process involves multiple precise and controlled steps to build the intricate structures within microchips. Among these steps, nitrous oxide is critical in various stages, contributing to layer formation, material enhancement, and defect mitigation.

Oxidation Processes: Building Silicon Dioxide Layers

One of the fundamental applications of nitrous oxide in semiconductor fabrication is in thermal oxidation. When N₂O is introduced into a high-temperature furnace, it reacts with silicon to create a high-quality silicon dioxide (SiO₂) layer on the wafer’s surface.

This thin oxide layer acts as:

- An insulating barrier between transistors

- A gate dielectric in MOSFETs (metal–oxide–semiconductor field-effect transistors)

- A protective layer against contaminants

Compared to other oxidizing agents, nitrous oxide produces oxide films with better electrical characteristics and lower defect densities. This results in higher chip reliability and better performance.

Chemical Vapor Deposition (CVD) Enhancement

Nitrous oxide also plays a crucial role in Chemical Vapor Deposition (CVD), particularly in Low-Pressure CVD (LPCVD) processes used for depositing dielectric films like SiO₂ or silicon oxynitride.

Benefits of N₂O in CVD:

- Produces uniform and high-purity films

- Minimizes contamination during deposition

- Enables precise thickness control, critical for advanced node chips (e.g., 5nm and below)

The controlled introduction of nitrous oxide into CVD chambers ensures consistent film properties across large wafer batches, contributing directly to yield optimization.

Annealing & Defect Repair

During annealing, wafers are exposed to high temperatures to improve crystalline quality or repair damage from previous process steps like ion implantation. Nitrous oxide atmospheres are often used in Rapid Thermal Annealing (RTA) or furnace annealing because they:

- Reduce interface state density

- Repair silicon lattice damage

- Improve electrical characteristics of gate oxides

By incorporating nitrous oxide into annealing processes, manufacturers can enhance device reliability and minimize leakage currents, which are vital for cutting-edge semiconductors.

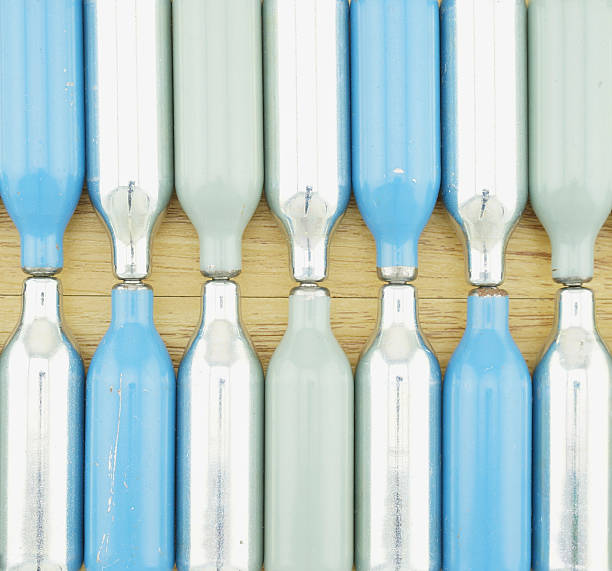

Storage and Delivery: The Importance of Industrial Nitrous Oxide Tanks

Because nitrous oxide is used in large volumes in modern fabs (fabrication plants), safe and reliable storage and supply systems are essential. This is where industrial nitrous oxide tanks come into play.

- High-purity containment: Semiconductor-grade N₂O must be stored without risk of contamination.

- Pressure resistance: Tanks must be engineered to withstand high pressures, often exceeding 750 psi.

- Leak prevention: Gas leaks can be dangerous and costly in fab environments. Tanks must be equipped with precision valves and fittings.

- Safety Protocols: Leak detection sensors, double-walled insulation, and SEMI F5-0221 compliance.

- Automated distribution: Modern facilities use advanced gas cabinets and distribution panels connected to central storage tanks, ensuring stable and continuous flow.

At Rotass, we offer robust industrial nitrous oxide storage solutions designed specifically for the demands of semiconductor production. Our tanks are tested for performance, purity assurance, and long-term stability.

Market Outlook and Growing Demand

The global demand for semiconductors is skyrocketing due to the expansion of 5G, AI, IoT, automotive electronics, and high-performance computing. This translates directly to an increase in industrial nitrous oxide usage.

- Miniaturization of chips requires thinner and more uniform oxide layers, increasing reliance on high-purity gases like N₂O.

- Expansion of fabs in Asia, North America, and Europe is pushing up demand for bulk industrial gas systems.

- Environmental regulations are encouraging safer oxidizers with lower toxic byproducts—nitrous oxide is often preferred over more reactive alternatives.

As chip geometries shrink and fab production scales up, suppliers must meet the volume, quality, and consistency requirements of next-generation chipmaking processes.

Need Reliable Industrial Nitrous Oxide Supply for Your Fab?

From forming silicon dioxide layers to enhancing film deposition and repairing wafer defects, industrial nitrous oxide has become a cornerstone in semiconductor manufacturing. Its stability, purity, and reactivity make it a versatile and efficient solution for advanced fabrication techniques.

As the industry grows, having a reliable gas supply chain is critical. With ROTASS, you get more than just a gas provider—you gain a technology partner committed to your production excellence.

Looking for industrial nitrous oxide or high-quality tanks for your semiconductor application?

Contact Rotass today to learn more!