2026 / 01 / 29

Bulk Cream Chargers vs Small Chargers: Which Is More Cost-Effective?

Table of Contents

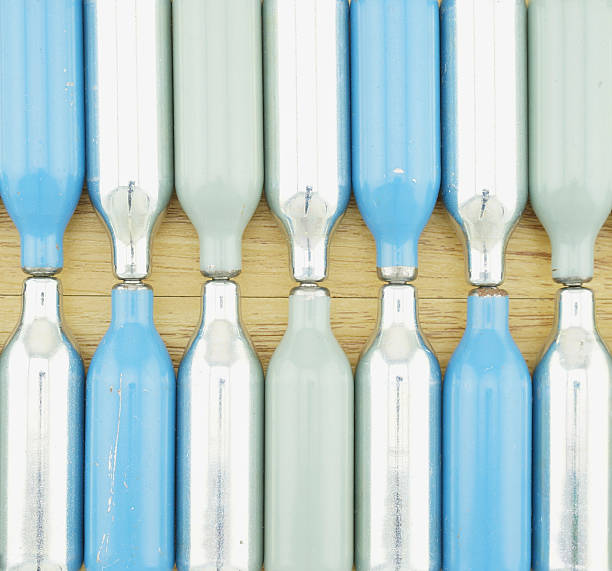

In coffee shops, bakeries or event catering settings, cream chargers are indispensable tools for daily work. For a long time, users have been accustomed to purchasing boxes of silver 8g small steel chargers. But in recent years, large tanks/cylinders (with capacities ranging from 580g to 2.2L or even higher, in sizes similar to thermos flasks or fire extinguishers) have been rapidly taking over the market.

Facing these two completely different specifications, many users can’t help but wonder: Should I stick to buying the cheap and portable small canisters, or should I upgrade to the larger chargers for a more cost-effective long-term solution?

This blog will provide you with a clear calculation from multiple aspects such as unit price, equipment investment, operation accuracy, and hidden losses, so that you can clearly understand how to make the right choice. Let’s continue reading!

1. Cost Per Shot

When we stand in front of the shelves, the most immediate impact is often derived from the prices. A small canister of nitrous oxide seems very cheap, costing only a few dollars to purchase; while a large container can cost several hundred dollars, seemingly representing a considerable expense. However, simply looking at the total price often leads to misinterpretation. We must introduce a unified measurement system: the cost per gram of N2O.

Small Cream Chargers

Traditional 8g gas cartridges are usually sold in boxes of 10, 24 or 50. Although the retail price is low, please note that what you purchase is not just the gas, but also a large number of metal casings. Each 8g gas requires an independent metal casing, coating and packaging box, and the manufacturing and logistics costs of each unit of gas are extremely high. The costs of these non-gas components are ultimately borne by the consumers.

Large Cream Chargers

Taking the common 580g canned version as an example, the net content of this can of gas is equivalent to approximately 72 8g small gas cartridges. The large can is essentially wholesale, eliminating dozens of independent packaging processes and significantly reducing the proportion of packaging materials in the total cost.

Therefore, in the comparison of the unit price of each gas, purchasing a large tank is usually 20% to 50% cheaper than buying small gas canisters of the same volume. If your consumption is high, this price advantage will accumulate to an astonishing figure over the long term.

2. Additional Equipment Costs

Since gas is cheaper in itself, why don’t everyone simply switch to large tanks? The reason is that there is an entry barrier and a fundamental difference in operation mode.

With the small air pump, you only need a standard cream dispenser, which is the most basic configuration. However, the small charger releases gas through a physical puncturing method, which will cause an instantaneous high-pressure impact. Frequent and prolonged “puncturing” operations will wear down the rubber sealing ring and metal pin inside the foaming gun, shortening the lifespan of the expensive foaming gun. Moreover, it is difficult to control the amount of gas – either it’s an entire 8g or none at all, and no fine-tuning is possible.

The large tank, due to its extremely high internal pressure and the inability to be directly inserted into the foaming gun, requires you to purchase two additional core components – the regulator and the connecting hose. This one-time additional investment is worth it as it brings about an upgrade in functionality. Through the regulator, you can precisely adjust the pressure of the injected gas according to the viscosity of the liquid. This is crucial for professionals who aim for perfect taste: you can set a high pressure for thick sauces and a low pressure for light foams. This controllability is something that the small air gun cannot offer.

3. Efficiency, Safety and Invisible Losses

In this fast-paced era, time is often equivalent to money, especially in a business context. At the same time, safety is also a factor that cannot be ignored.

The continuity of the workflow: If you are running a busy coffee shop or organizing a large party, using 8g small air guns means you need to repeatedly perform the actions of “unscrewing the gun head, removing the cold empty bottle, inserting the new bottle, tightening the inflation, and shaking”. This not only disrupts the work rhythm but also makes it prone to errors in the hustle and bustle. In contrast, a system connected to a large tank can work continuously, filling dozens of bottles of cream without interruption, significantly improving the cup-making efficiency.

Safety and Frostbite Risk: When using small gas cylinders, the instantaneous release of gas absorbs a large amount of heat, causing the surface of the cylinder to rapidly cool down. If the operation is improper or the hands are wet, users have the risk of being instantly frostbitten. In contrast, the large tank system delivers gas through a hose over a long distance and is equipped with a pressure gauge for monitoring. The operation process is more controllable, significantly reducing the physical risk of direct contact with extremely low-temperature gas.

The hidden waste of gas: Sometimes small gas cartridges may encounter dud chargers or experience minor leaks during disassembly. Although this seems insignificant, the accumulation over time is still a form of waste. Large cans combined with pressure relief valves can achieve total utilization of gas through pressure gauge readings. Every gram of gas can be converted into a product.

4. Waste and Environmental Protection

Apart from the economic aspect, disposing of waste is also a “hidden cost”. Imagine that after using up 580g of gas, if you use small gas cartridges, you will receive approximately 72 scattered metal containers with residual gas odors. Sorting, collecting and processing these fragmented metal waste is not only cumbersome but also requires a large amount of storage space. In some areas, small steel cylinders containing residual gas are even classified as difficult-to-handle hazardous waste.

In contrast, the large tank solution would only result in an empty steel cylinder. Most modern large tanks are equipped with pressure relief devices, and after emptying, they can be directly treated as recyclable metals, which is more environmentally friendly and easier to manage.

5. Which One Should You Choose?

Since both specifications have their own advantages, based on the above analysis, we can provide you with clear recommendations according to your usage frequency and requirements:

Home baking beginner / Extremely infrequent user

You might make desserts only once every two weeks, or simply to add a touch of ceremony to a holiday feast. Your kitchen space is limited and you don’t want to store complex equipment.

Rotass recommendation: Choose the 8g small charger. The amount of this size is insufficient to offset the additional cost of purchasing the pressure reducing valve. The small charger can be used as needed and there is no pressure for equipment maintenance. It is your most flexible and low-barrier option.

Catering professionals / baking enthusiasts

This type of users need to frequently make cream, have specific requirements for the texture of the cream, or consume more than 50 small cans of cream per month.

Rotass recommendation: Large tanks of 580g or more. Although you need to purchase a set of valves first, this cost can usually be recovered by saving the gas difference after using 2-3 cans of gas. What’s more important is that the pressure control ability and the smoothness of continuous operation it brings will make your production process more professional and effortless.

The concept of cost-effectiveness is not merely about the listed price; it is a dynamic balance. If your goal is to minimize the cost of a single attempt and ensure convenience, choosing a small canister is highly suitable. However, if your aim is to achieve long-term low operating costs, precise product control, and less waste, a large container is the inevitable choice.

Anyway, if you are considering upgrading your equipment, it is recommended to first check your current inventory and your purchase records for the past three months. If the average monthly consumption is consistently above one box (50 pieces), then now is the perfect time to purchase the large tank sets with pressure relief valves. This not only saves money but also represents a professional upgrade for your products.